Product Parameters

| model | BY-GYFJ-series |

| refrigerant | freon |

| application area | Freshness preservation, refrigeration, freezing |

| Refrigeration capacity | 2KW-150KW |

| voltage | 380V |

| fin material | Copper, Aluminium, Steel, Stainless Steel Be Viabl |

| Specification | customized |

| noise level | Low |

| Installation method | Suspended ceiling and floor standing |

| customs code | 8479600000 |

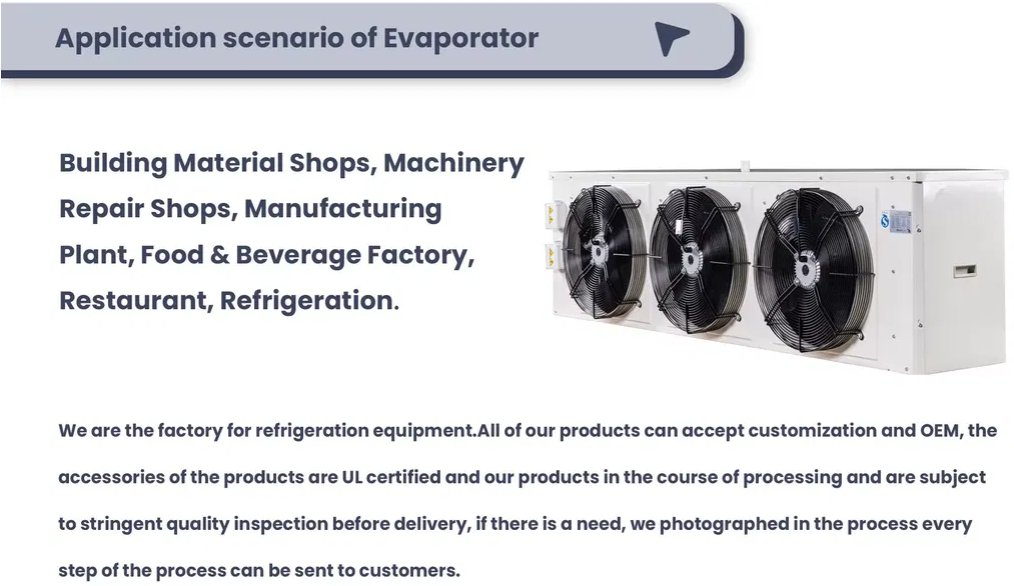

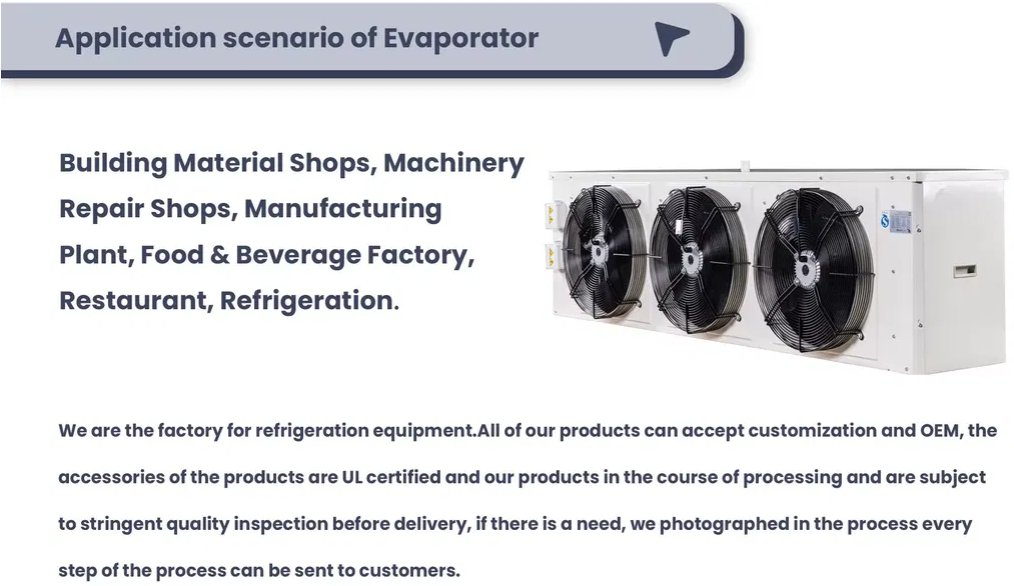

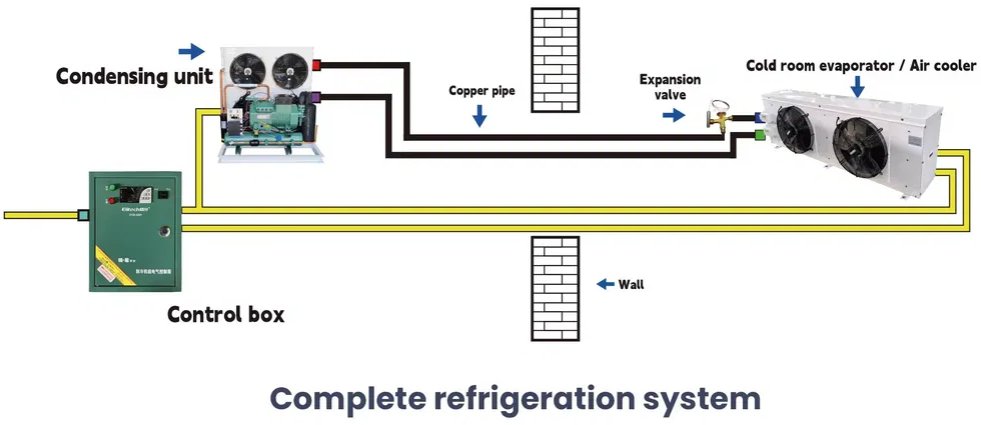

Air coolers can be used in varies cold stores such as architectural or constructional ones.D air coolers include DL,DD and DJ three series.DL series can be used all of 0 ºC for storing eggs and Vegetables,DD series at -18ºC around for storing meat and fishes.DJ series at -25ºC around for freezing the fresh food such as meat,fishes and son on.

Product Introduction:

Shell: High-quality steel plate applied with low-temperature resistant powder with strong corrosion resistance performance. Aluminum plate or stainless-steel shells can also be customized. All tube plates are made of 2.0 thick aluminum alloy plates in order to minimize the possibility of internal leakage caused by heat exchange copper tube wearing ascribed to thermal expansion and contraction.

Double-layer water tray: The outer water tray plate is in hinged lap design form, which facilitates inspection and maintenance. Ribbing slope design at the bottom of water tray could speed up drainage and avoid icing and corrosion. The inner water tray is covered with aluminum plate to reduce air bypass and improve fan efficiency and defrosting effect.

Heat exchange pipe: Efficient internal thread pipe from premium brand with optimized loop, and positive triangle staggered design in order to improve heat exchange efficiency.

Fin: Classic Europe-style sinusoid corrugated aluminum fin, which could improve air disturbance and enhance heat exchange capacity at air side significantly.

Fan: Customized high-power fan with external rotor (operating temperature: -40ºC~60ºC). Insulation class of motor: Grade F, which could ensure stability and reliability;

Defrosting: Stainless steel electric heating pipe with a low power and density. It is reasonably arranged inside coil and on the inner water pan to ensure more uniform heating effect, increase defrosting effect and prolong the service life of electric heating pipe.

Electrical junction box: Special customized electrical junction box, which could resist water, fire and high-voltage and be wired easily.

Factory testing: Air cooler is cleaned and inspected and has passed 25bar pressure holding test prior to delivery.

Sheet spacing: Standard values: 4.5mm, 6.0mm and 9.0mm, in order to meet different temperature and humidity requirements.

Different refrigerants: Meet the requirements of refrigerants including R404A, R507A, R134a, R22, etc.